Milwaukee Electronics was founded in 1954, offering services in circuit board design and PCBA assembly to the mining industry in the Wisconsin, USA, region. My father, P. Michael Stoehr purchased the company in 1985 with the mission of creating a business that would put customers first and be a fulfilling place to work for the employees serving those customers.

As the second generation to take the Chief Executive helm, it is very important to me to carry on my father’s customers-first legacy and to ensure that Milwaukee Electronics maintains the entrepreneurial spirit that has allowed the company to continually expand its range of services, maintain decades long customer relationships and provide careers for many dedicated employees.

Our services include:

I understand that by becoming a customer of ours, you are trusting us with your future success. It is my mission as CEO to ensure that Milwaukee Electronics and its business units are worthy of that trust. Contact Us to see how we can serve as your manufacturing partner.

JERED STOEHR

Chief Executive Officer

OUR HISTORY: AN INTERACTIVE TIMELINE

The pace of competitive change continues to increase and sourcing teams continually face new challenges. Engineering support staffs are shrinking. Market demand is difficult to forecast. Cost pressure continues to increase. In order to deliver extraordinary results, your team needs a responsive contractor who can seamlessly integrate into your product realization strategy.

Milwaukee Electronics has developed a business model that addresses key customer issues:

With manufacturing facilities in Wisconsin, Oregon and Mexico, we offer both U.S. regional support options and a migration path to a low cost manufacturing solution for mature product. This model improves responsiveness, shortens finished goods pipelines and preserves U.S. jobs.

Product development and early prototype phases require a unique mix of support services. Our business model uses strategic business units to address these needs, providing customers with focused, responsive teams for both product development engineering support and quick-turn prototyping.

Materials represents the bulk of product cost. Our International Purchasing Office (IPO) in Singapore helps ensure competitive offshore materials options. Our India office helps speed machine programming and access lower cost engineering support, as required.

We combine a Lean manufacturing philosophy with a strong program management model to provide efficient, rapid solutions to our customers' most challenging requirements.

Milwaukee Electronics is privately-held and financially strong. We have served some of our customers for decades. While we continue to evolve in terms of global reach and overall capabilities, our commitment to putting customers first remains unchanged.

With over 70 years of experience providing product development expertise, printed circuit board

(PCB) assembly, box build and post-manufacturing, Milwaukee Electronics has significant expertise

over a wide range of industries.

Our facilities in Milwaukee, WI, Portland, OR and Tecate, Mexico support both customers wishing to have manufacturing in close proximity to their product development teams or manufacturing facilities, and those who wish to access the lower cost advantages of Mexico.

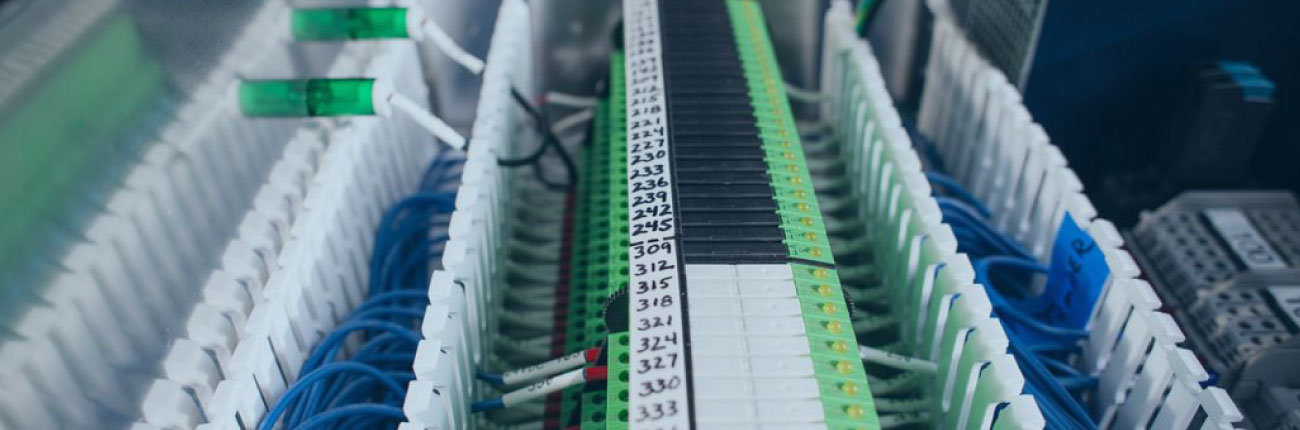

While we have excellent PCB assembly capabilities, we are also a strong source for electromechanical and mechanical products. Our support capabilities in this area include potting, conformal coating, custom motor manufacturing, coil winding and the ability to design efficient work cell assembly operations for virtually any electromechanical or mechanical assembly project.

Our Screaming Circuits subsidiary offers a range of solutions for prototypes and low volume production and is co-located with our Portland, OR EMS operation for easy transition to volume production. Our Milwaukee, WI location compliments our Portland facility by focusing on volume production and our Tecate facility is an excellent option for older margin sensitive products needing to migrate to a low cost country. We also have significant expertise with long lifecycle products and product near end-of-life.